Method and importance of lens grinding accuracy control in the manufacturing of optical systems of instrument making

in the manufacturing of optical systems of instrument making

In the field of optical system manufacturing, the accuracy of lenses directly affects the performance of the final optical equipment. The accuracy of lenses is mainly determined by the grinding accuracy of lenses, therefore, the control of lens grinding accuracy has become an important link in optical system manufacturing. This article will discuss the methods and importance of lens grinding accuracy control.

lenses directly affects the performance of the final optical equipment. The accuracy of lenses is mainly determined by the grinding accuracy of lenses, therefore, the control of lens grinding accuracy has become an important link in optical system manufacturing. This article will discuss the methods and importance of lens grinding accuracy control.

The methods of lens grinding accuracy control mainly include the following several kinds:

Using high-precision grinding equipment: By using high-precision grinding equipment such as high-precision grinding machines and polishing machines, the accuracy of lenses during the grinding process can be guaranteed.

Using reasonable grinding processes: According to the characteristics of the lens material and the specific requirements of the lens, appropriate grinding processes such as single-sided grinding, double-sided grinding, and polishing are selected to ensure the grinding accuracy of lenses.

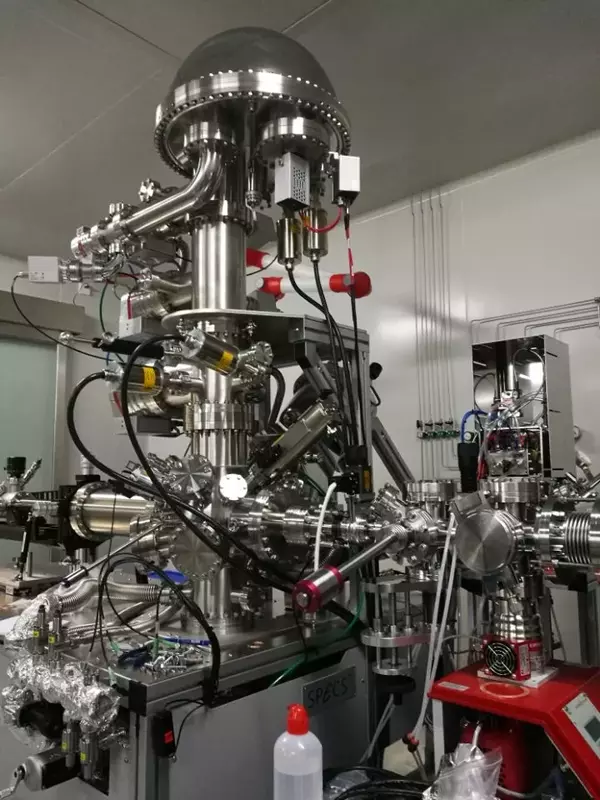

Using precise measuring tools: Using precise measuring tools such as laser measuring instruments and interferometers to precisely measure the size, shape, and surface quality of lenses, and to detect and correct deviations in a timely manner.

Strictly controlling environmental factors: The lens grinding environment needs to maintain a constant temperature and humidity to reduce the impact of environmental factors on lens accuracy.

lens accuracy.

The importance of lens grinding accuracy control is mainly reflected in the following points:

Ensuring optical performance: The accuracy of lenses directly affects the imaging quality of optical systems, including image clarity, contrast, and dispersion. Only by ensuring the accuracy of lenses can the performance of optical systems be ensured.

Improving product quality: The control of lens accuracy is the foundation for ensuring the quality of optical system products. Only by ensuring the accuracy of lenses can high-quality optical system products be produced.

Resource conservation: During the lens grinding process, if the accuracy control is not good, a large number of waste products may be produced, causing waste of resources. By precisely controlling the accuracy of lenses, waste products can be effectively reduced, and resources can be conserved.

Improving production efficiency: By precisely controlling the accuracy of lenses, the production cycle can be shortened, and production efficiency can be improved. At the same time, through precise control of the accuracy of lenses, the number of rework can be reduced, and production costs can be lowered.

In summary, the control of lens grinding accuracy is an indispensable part of optical system manufacturing, its importance is self-evident. By adopting high-precision grinding equipment, reasonable grinding processes, precise measuring tools, and strict environmental control, the accuracy of lenses can be effectively improved, thereby enhancing the performance of optical systems, improving product quality, conserving resources, and increasing production efficiency.